The progressive cavity pumps and pumping solutions from Seepex, Germany, are used in

- raw material processing,

- electrode material production,

- film and cell production and

- battery recycling.

The progressive cavity pumps convey binders, additives and active ingredients in perfect doses. The company also supplies pumps for the efficient production of electrode pastes. “As a globally sought-after specialist for progressive cavity pumps, pump systems and digital solutions, Seepex is helping to make the transition to greater sustainability a success,” says Thomas Dufner, Battery Market Manager at Seepex.

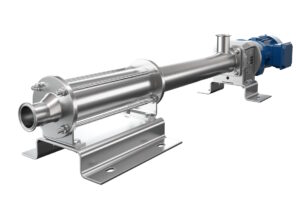

“Operational safety and maximum cleanliness when using valuable dispersed raw materials were the driving forces behind the development of the BF range. It helps reduce total cost of ownership and improve energy efficiency in virtually all battery applications by eliminating contamination and being easy to maintain. Cleaning cycle failures and disposal of contaminated battery compounds are not only wasteful, but also very costly,” says Dufner. “Chemical resistance and chemically compatible materials are necessary to prevent contamination of expensive raw materials. With BF, we assure that the materials are chemically compatible. The stainless steel design and flexible titanium shaft ensure contamination-free product quality. Contamination by oil or grease is impossible. The pumps can be thoroughly cleaned with common solvents and deionized water.”

The new BF range can be installed quickly, has a flow rate of up to 30 m³/h and operates at a pressure of up to 12 bar. It is available in block or bare shaft design and can meet customer-specific drive requirements. A TA-Luft or ATEX certified version is also available.

Reduce maintenance time and total cost of ownership

The BF pump is ensuring safety, cleanliness, high product quality and, last but not least, cost efficiency. The maintenance-friendly design reduces downtime and the total cost of ownership (TCO).

The clamp connections for quick installation/removal and the removable rotating unit simplify replacement and maintenance work.

The progressive cavity pump principle ensures a high dosing accuracy, resulting in better coating results and more accurate slurry recipes.

Thanks for the blog loaded with so much information. It’s really informative.

industrial pump supplier

Comments are closed.