New Stainless Steel Air Operated Double Diaphragm Pump up to 3” in Size

The Spanish pump manufacturer Samoa offers a new series of AODD pumps, from sizes ½" to 3”, manufactured in stainless steel. These versions provide...

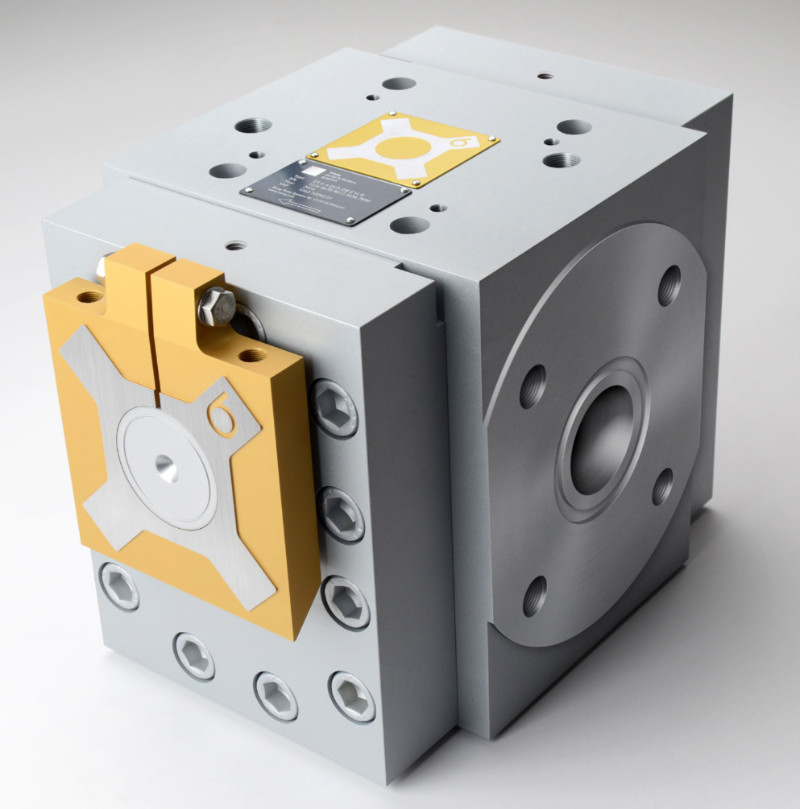

Maag Group is presenting innovative solutions that enhance the circular economy at Fakuma 2023,...

Maag is a broadly diversified global solutions provider of polymer pump & filtration systems, pelletizing & pulverizing systems, recycling systems and digital solutions. Maag...

Empowering E-Future: New progressive cavity pump tailored to the Battery Industry

The progressive cavity pumps and pumping solutions from Seepex, Germany, are used in

raw material processing,

electrode material production,

film and cell production and

...

The Pump Video of the Month: Smart Air Injection – the patented sludge...

Environmental aspects and economic considerations play a decisive role, when municipal water works are considering the purchase of modern pumping technology. Worldwide, Seepex's energy-efficient...

ISH 2023 Germany: KSB will show new in-line pumps for building services applications

At ISH trade fair (13 to 17 March 2023) in Frankfurt (Main), KSB is showcasing a new type series of fully integrated in-line water pumps. The highly efficient EtaLine Pro...

Pumps enabling production of 3 billion liters of renewable fuels from waste at one...

Sulzer has supplied flow technology solutions to convert an existing US West Coast refinery into one of the world’s largest renewable biofuels plants. The...

Evaporator circulation pumps in a fertilizer plant

One of the world’s top fertilizer producers operates a big fertilizer complex in South America. A few years ago, the company started an expansion...

Turning water into wine – pumps help Australian vineyards improve irrigation efficiency

Australian wine is world-renowned, and vineyards across the country go to great lengths to grow the perfect grape. Irrigation is paramount to achieve this...

A straightforward solution to a complex problem by targeted pump refurbishment that achieves 50...

Pushing older equipment to meet an increased duty requirement can sometimes result in reliability issues down the line. However, achieving this by sourcing newer...

Building flood defences to stand the test of time

Looking ahead at rising sea levels, water utilities in low-lying areas need to be planning how to handle increased risks of flooding. In Denmark,...