The use of elbow pumps is always indicated when large flow rates are to be pumped to low heads. This requires a propeller-like impeller with both axial inlet and outlet, which guides the out warding flow into a pipe bend. This geometry then allows the introduction of a long projecting pump shaft in the pipe bend up to the impeller. The bearing of the pump shaft takes place outside the pumping chamber and must be generously dimensioned in the axial direction. The adjustment of the delivery head is usually done with a belt drive between the pump shaft and motor. The new ROPP model – showcased at Achema 2018 – of the Germany based pump manufacturer Wernert is also based on this classic pump concept, but with a few additional technical features that should be of interest to the experts and pump users in the chemical industries:

The use of elbow pumps is always indicated when large flow rates are to be pumped to low heads. This requires a propeller-like impeller with both axial inlet and outlet, which guides the out warding flow into a pipe bend. This geometry then allows the introduction of a long projecting pump shaft in the pipe bend up to the impeller. The bearing of the pump shaft takes place outside the pumping chamber and must be generously dimensioned in the axial direction. The adjustment of the delivery head is usually done with a belt drive between the pump shaft and motor. The new ROPP model – showcased at Achema 2018 – of the Germany based pump manufacturer Wernert is also based on this classic pump concept, but with a few additional technical features that should be of interest to the experts and pump users in the chemical industries:

- All wetted components are made of non-metallic materials which are resistant to corrosion and abrasion. The material UHMW-PE for impeller, stator and pump housing is a proven, cost-effective and extremely wear-resistant plastic available.

- Alternatively, the pump can be equipped with thick-walled PTFE components for maximum corrosion resistance.

- The shaft seal is realized with the tried-and-tested Wernert bellows mechanical seal. Optionally, the use of a double seal HRZ 13 is also possible.

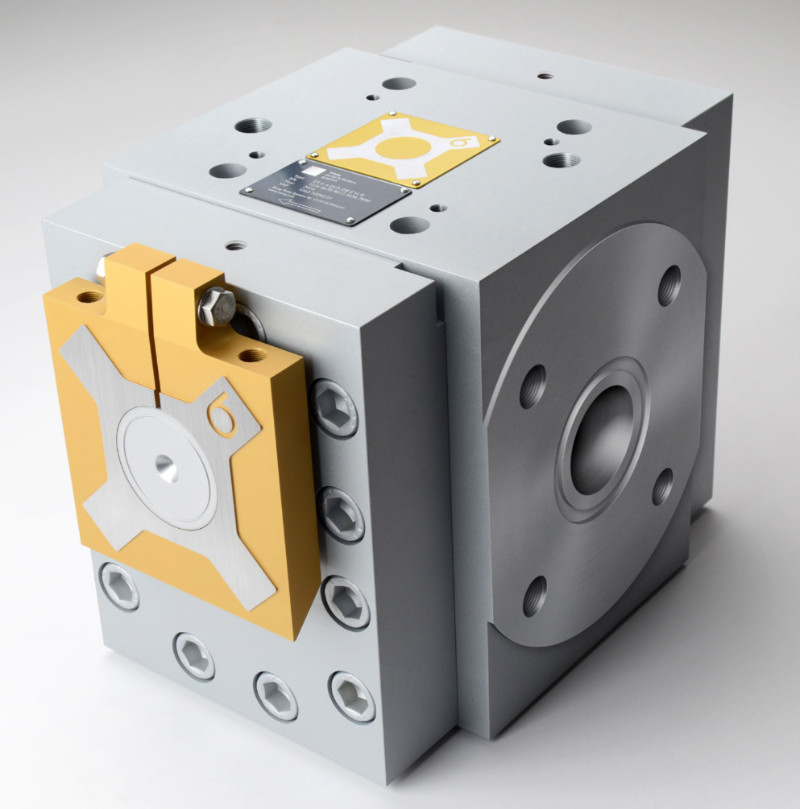

- In contrast to conventional designs, the electric drive is actively integrated into the design as a flange motor. In combination with a patent-pending bearing arrangement, the ROPP presents itself as a compact unit with surprisingly easy access to the belt drive.

The new ROPP pump delivers a flow between 750 and 2000 m³/ h at a delivery height of up to 9 m.