A German energy supplier had initially used a geological horizon for gas storage, but then decided to extract crude oil from the same deposit. Therefore, a suitable extraction system had to be acquired for transporting the multi-phase mixture with a high gas content to the surface from 1,200 m below. Due to the extreme conditions, a special pump technology was required:

A German energy supplier had initially used a geological horizon for gas storage, but then decided to extract crude oil from the same deposit. Therefore, a suitable extraction system had to be acquired for transporting the multi-phase mixture with a high gas content to the surface from 1,200 m below. Due to the extreme conditions, a special pump technology was required:

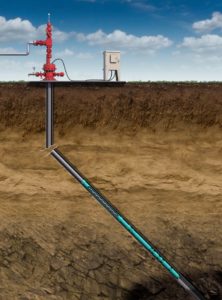

Netzsch developed a progressing cavity pump system with submersible drive. As all moving parts are positioned deep down in the well, there is also no risk of environmental impact from leaks at the surface.

The conditions on site presented high requirements for the pump design: as the medium is a multi-phase mixture with a very high gas content. Progressing cavity pumps, which are normally used in Central Europe until now, have been systems with above-ground drive. These units have a dynamic seal on the surface which has a significant disadvantage in case of extreme pressure increase on the intake side: the seal can become overloaded and trigger a blowout.

To exclude this risk, Netzsch decided on a progressing cavity pump which is driven underground – the ESPCP. The special feature of this pump is that the rotor-stator combination and the motor are sunk into the well. The motor is connected directly to the rotor via a short flexible rod. All radial and axial forces of the rotor are absorbed by a special underground bearing housing. In addition to this, the dynamic seal is also located in the 1,200 m deep well. This moved all critical components of the pumping solution below ground, precluding environmental impact from leaks above ground.