Kanchan is an aerospace engineer and computational fluid dynamicist by training. She now drives the development and promotion of SimScale’s technology in the rotating machinery industry.

Author: Kanchan Garg

Simulation and analysis tools allow engineers to explore, test, validate, and optimize product ideas and designs through the use of computational fluid dynamics (CFD), heat transfer, and structural analysis. The advanced physics solvers available to designers and engineers empower them to study & optimize pressure drop and force behavior, evaluate fluid flow patterns, minimize (or even leverage) cavitation effects, analyze vibration impacts, and more. By deploying simulation early in the product design process, turbomachinery & pump engineers can ensure that they meet and in most cases, exceed their design validation requirements.

Modeling provides detailed insights into performance characteristics, allowing engineers to identify design strengths and weaknesses in a virtual prototype, avoiding costly physical testing & prototype rework. The resultant time & cost savings from simulating early and often allows engineers to explore more of their ideas, sparking innovation which leads to competitive insights.

A typical workflow is to import a CAD model of a pump for example, select what analysis type to perform (fluid, structural, thermal), set up simulation parameters and boundary conditions including material selection, discretize the CAD domain (Meshing), and simulate and analyze the results.

Legacy simulation tools limited to desktop hardware have been a limitation to the wide scale and economical adoption of simulation for engineers in all industries. A new generation of cloud-native simulation tools accessed via a web browser, with faster algorithms and simpler user interfaces, are enabling the use of simulation across teams and entire organizations earlier in the design process.

Advances in Pump Simulation & Design

Turbomachinery products and components need a special set of simulation tools due to their unique properties. Modern cloud-native tools now have robust CAD handling capabilities to let engineers spend less time on making their models simulation ready, and more time on analysis. Automated binary tree-based meshers can do this without any input from the engineer, who can spend more time evaluating subsonic and supersonic flow behavior, turbulence effects, cavitation, and multiphase flows. The accuracy of these solvers is close to 2% as compared with test data and a designer can calculate an entire pump curve, by simultaneously running multiple simulations in the cloud, in 15 minutes. This is possible using input parameterization for fast design prototyping and CAD associativity for easy geometry variation.

The toolset is encompassing and includes multiphysics analyses for instance:

- Static and dynamic analysis for peak structural stress, deformation, rotor/shaft strength analysis

- Vibration and harmonic analysis to reduce noise and long-term fatigue

- Thermo-structural shock analysis

- Transient thermal stresses during pump operation

- Multiphase analysis for flows of mixtures e.g. water/oil

- Designers of pumps can now generate an entire pump curve for a specific blade geometry and calculate performance curves for multiple pump designs in parallel.

Making use of application programming interfaces (API) extends the use of simulation tools to include third-party optimization and design of experiment (DOE) tools.

Pump Efficiency in Your Web Browser

In the pursuit of energy efficiency, most countries have implemented stringent energy efficiency standards for the production and operation of water pumps such as the Minimum Energy Index (MEI) requirements of the European Union (EU) and the similar Pump Energy Index (PEI) outlined by the U.S. Department of Energy (DoE). Original equipment manufacturers (OEMs) must ensure compliance with the latest energy efficiency regulations which leads to significant R&D and physical testing overheads. Similarly, end users of pumps are demanding lower energy and operating costs and increased reliability. Digitally testing the design of pumps is now a cost-effective alternative being rapidly adopted by leading engineering firms worldwide.

Cloud-native, multi-disciplinary simulation solutions for the overall design and performance assessment of pumps are available through a simple login and web browser. Users can now spend only a few minutes to set up and run a complete pump simulation including calculating the full pump curve within minutes and predict flow, head, power at part load, BEP, and overload conditions. These lead to the estimation of MEI, PEI, and energy rating metrics required to demonstrate compliance with standards.

Case Study of Energy-Efficient Water Pump Design

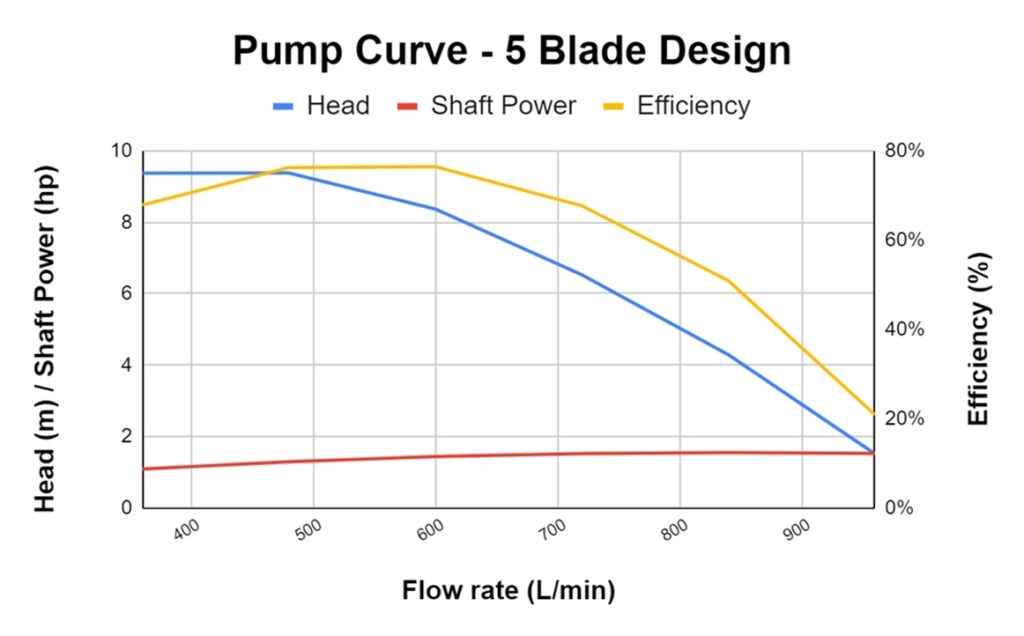

We show readers a study on energy efficiency for an end suction close coupled (ESCC) pump where we generate a pump curve using CFD. The simulated data is then exported to a spreadsheet tool that calculates pump efficiency index figures according to a specific standard. Design parameterization is also used to edit CAD parameters and run scenario analysis to compare energy ratings.

The Commission Regulation (EU) No 547/2012 that is effective from January 2015 states that water pumps should have a minimum efficiency MEI of 0.4 and is applicable to five types of water pumps including ESCC. These requirements are accompanied by the European test standard EN 16480 and only pumps that pass the test standard can be CE-marked and sold in the EU.

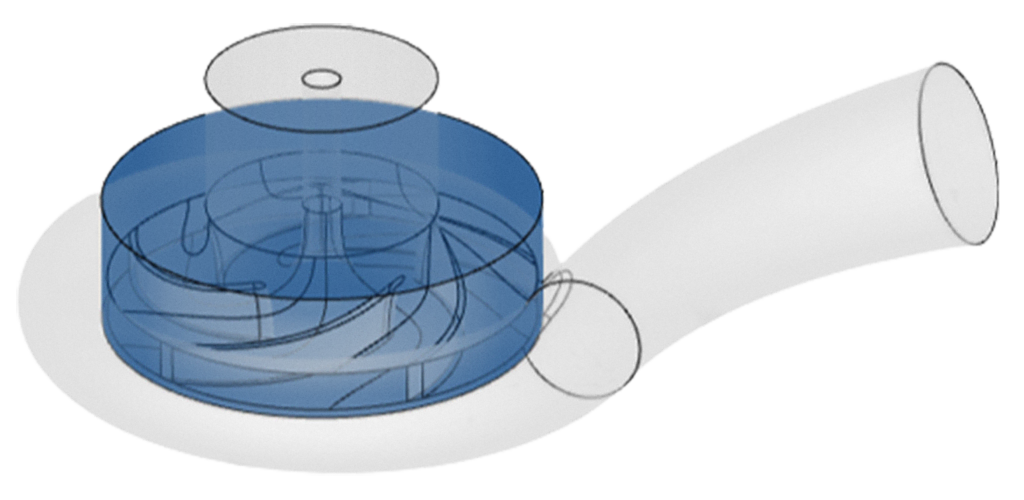

The geometry of the pump is shown in the image above and two CAD variations are compared. Both impeller diameters are 6 inches:

- Baseline: 5-blade impeller

- Modified: 6-blade impeller

The following simulation conditions are used:

- Inlet Definition

- Static pressure: 0 Pa (gauge); 101.3 kPa (reference)

- Outlet Definition

- Velocity Outlet: 21.6 – 57.6 m3/hr

- Impeller Rotation Definition

- Rotational axis: anticlockwise

- Rotational Velocity: 1,800 RPM

- Motor efficiency 95%

- Physics Definition

- Flow Material: Water (Incompressible)

- Turbulence: Fully turbulent flow modeling

- Time Dependency: Steady State

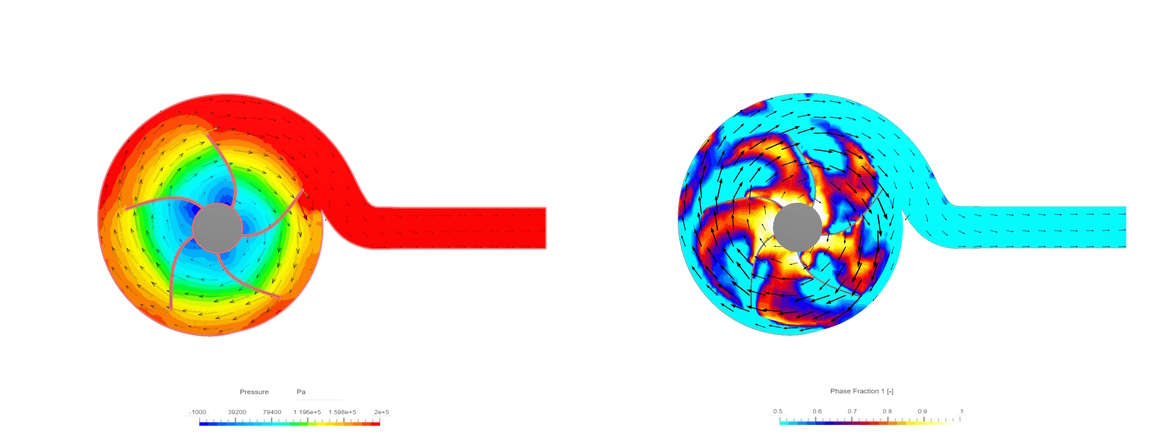

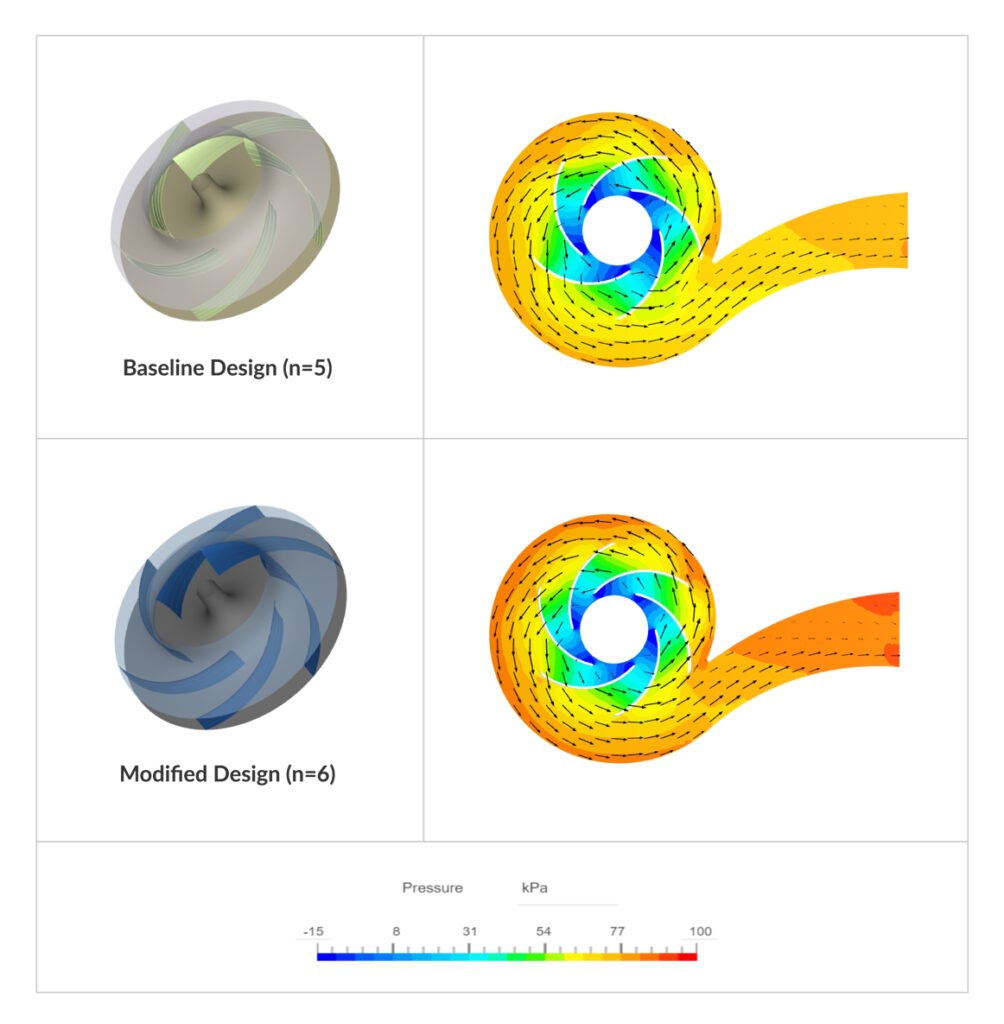

- Design Comparison – Pressure Contour and pump performance

Results & Analysis

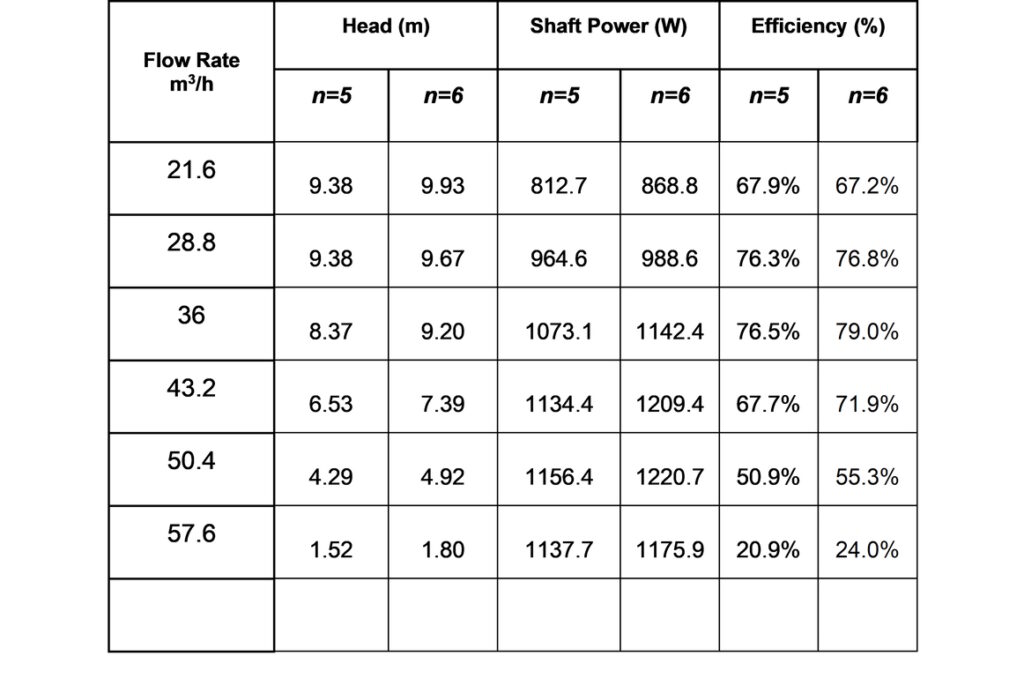

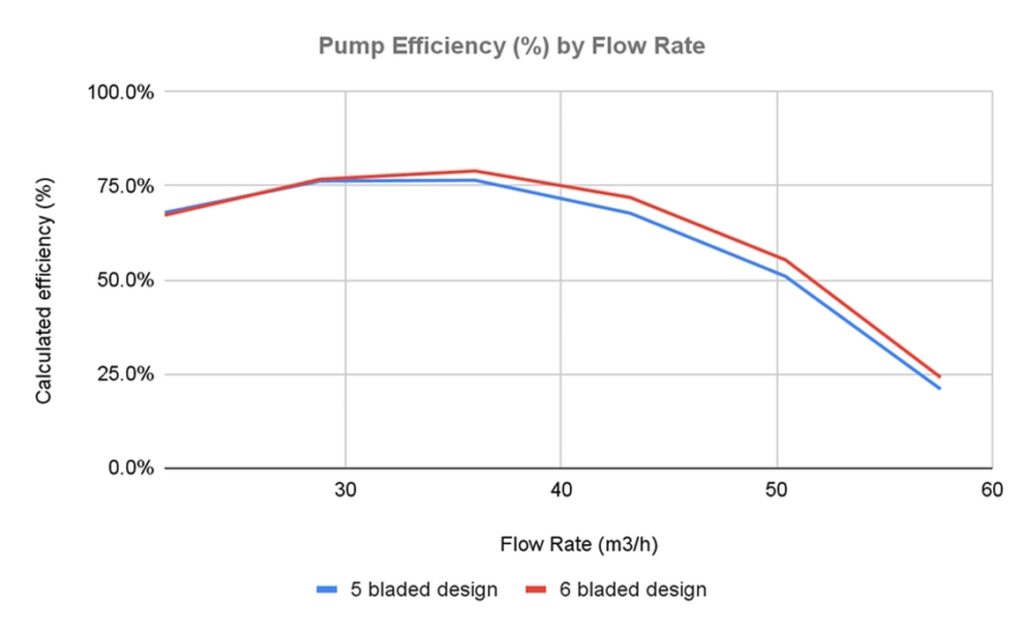

The image below illustrates pressure contours on the two designs. In a matter of minutes, we can see pressure and flow visualization through the pump and also extract quantitative data such as efficiency, static head, and PEI rating for the two designs. It should be highlighted that both designs were simulated in parallel in the cloud. Simulating two options would take the same time as analyzing just one geometry. Likewise, a designer might have simulated a dozen pump geometries in parallel with no additional time. Charts showing the hydraulic efficiency, static head, and shaft power required against flow rate are also shown. Using the Hydraulic Institute Pump Energy Index Calculator we have calculated that the PEI of the 5-bladed design is 0.94 against 0.77 for the 6-bladed design. The table below shows data for head, shaft power, and efficiency at various flow rates and the chart below shows a comparison of flow rate against efficiency for the two designs.

Summary

Using simulation to optimize the design and performance of pumps is essential for innovating high-performing pumps that last. With advances in simulation technology and the associated infrastructure of access, storage, computing power, and collaboration all in the cloud, accessed via a web browser, engineers can leverage these tools more easily than ever before.

About SimScale

SimScale GmbH has developed the world’s first fully deployed cloud engineering simulation platform. SimScale allows the engineer to test their designs against real-world physics using a powerful CFD engine accessed through a web browser. The SimScale Community Plan is accessible for engineers to begin simulating their projects.