Technical paper by Paolo Zenone

Meccanotecnica Umbra (MTU) provides not only mechanical face seals for uses from dishwashers to Oil & Gas applications, but the company’s mission is also to support customers during their search for a sealing system. Pump manufacturers and pump users often need assistance to identify the right solution for their equipment. As Meccanotecnica Umbra pushes into a new high-value market, looking to new products that can be disruptive to the State of The Art, a co-designing approach is mandatory, striving to put ourselves in our clients’ shoes. This is the main reason why the Meccanotecnica Umbra R&D department is used to designing both the new product and the test rig for simulating working conditions.

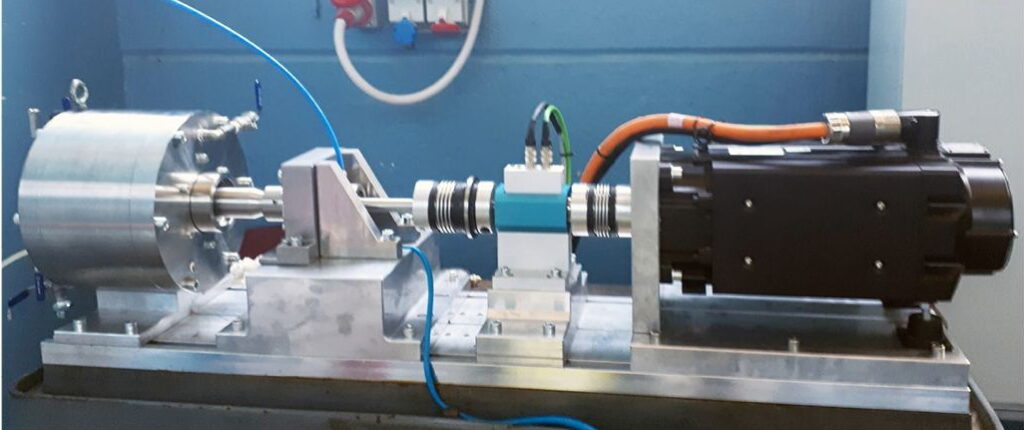

For low and medium-duty applications, MTU developed a test bench characterized by a modular approach: the idea is building “just one flexible tool” that can test sealing setup for shaft diameter ranges between Ø 10 mm and Ø 80 mm. With this test equipment MTU reached this goal by designing a test chamber where it is possible to change the counterface seat and the shaft in a plug&play manner. Moreover, also the layout of this test bench follows a modular strategy, as you can see in the picture (Fig. 1).

From left to right, you can see the electric motor that can reach more than 4000 rpm with a maximum torque of 50 Nm, a torque sensor with a double range of 10 Nm and 50 Nm (that monitors both torque and speed), a bearing group that can withstand up to 40 KN of axial load (coming from the test chamber where the working fluid is pressurized) and, finally, the test chamber. Mechanical face seals can be tested simulating working conditions, using a setup of variables with the following ranges:

- Pressure: from atmospheric pressure to 40 bar

- Temperature: from room temperature to 150 °C

- Speed: from 0 to 4200 rpm both CW and CCW

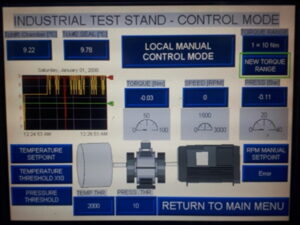

The test conditions can be moved during test running, creating a sort of test mapping, where a PLC can automatically change the testing parameters within the ranges described above. In this way, you can check the performance of the seals also dynamically, taking a step forward to real working conditions. All the parameters are visualized on a dashboard (Fig.2), and leakage rates can collect during the test.

Test bench for applications in the field of “renewable energy”

Renewable energy is a strategic topic for Meccanotecnica Umbra. The company started a challenging journey in this market by designing a new concept rotary joint for Concentrated Solar Plants (CSP), or more specifically a parabolic trough plant.

Because a completely new product had to be designed for very heavy-duty application (working temperature above 500 °C, operating pressure 40 bar, etc.), MTU had a complex goal: to build a test bench that could simulate extreme working conditions to measure the performance of our prototype. To do that, MTU faced some challenging aspects that we had never managed before:

- Thermal insulation for high temperature

Reaching high temperature is difficult but maintaining it requires great effort. MTU spent a lot of time finding the right insulation material to make a thermal blanket wearable by this special test bench. The sealing specialists couldn’t just cover the hot surfaces, also for safety reasons, but the company had to guarantee relative movement and easy disassembly.

- Safe management of molten salt: filling up and draining the test rig

Molten salt can melt a ring of tungsten carbide in hours, so MTU had to plan a safety procedure for all the testing phases from filling up to draining. The specialists in the R&D department designed a physical barrier all around the test bench and a suction system to expel any gas coming from molten salts.

- Joule effect heating system: measuring and controlling high current intensity

Molten salts are the HTF (Heat Transfer Fluid) used in the CSP plant. One of the main issues in using this fluid is its high melting temperature, close to 250 °C. To avoid any clogging in the manifold, a Joule effect heating system is used in the plant: a high-intensity current (400 A) flows into the pipe, maintaining the temperature above the melting point. Because the MTU prototype is directly connected to the manifold of the plant, it has to manage this current flow and we need to simulate that aspect on the test benches. For that reason, MTU developed a constant current generator that can provide a current intensity of 400 A, at low voltage, as in the real plant.

Test bench for “well drilling” applications

In Oil & Gas applications, especially for well drilling, high pressure is a standard working condition: in an oil drilling well, the mud pumped into the drilling pipe can reach more than 500 bar. Abrasive working fluid with high pressure is a terrible mix for mechanical components and reliability is a must to avoid failures and very expensive maintenance activities.

Meccanotecnica Umbra designed a high-pressure joint that can withstand these harsh working conditions: but to do that, MTU also needed to design the test rig to measure its performance. The test rig has 4 main components:

- Test chamber – it can test 3” and 4” washpipe rotary joints reaching a maximum pressure of 600 bar

- Pressure control unit

- Electric motor

- DACS (Data Acquisition Control Unit)

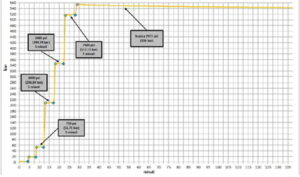

The test bench can test the rotary joint in compliance with the test procedure shown in Figure 5.

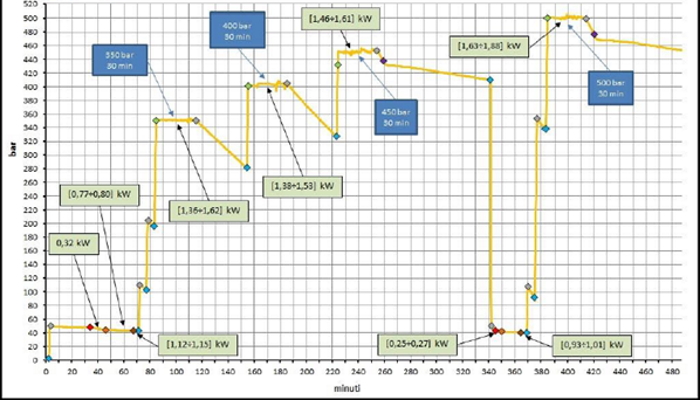

Moreover, the MTU specialists can carry out a dynamic test, changing pressure and speed values, monitoring temperature, and mechanical power. The DACS system makes a log file of all the testing parameters and manages critical conditions, stopping the test automatically (Fig. 6).

Here you will get more information

And see another MTU article here.