Textiles and other unconventional debris can be a tough problem for pumped wastewater systems. That’s why more and more operators are addressing the problem at source with grinders.

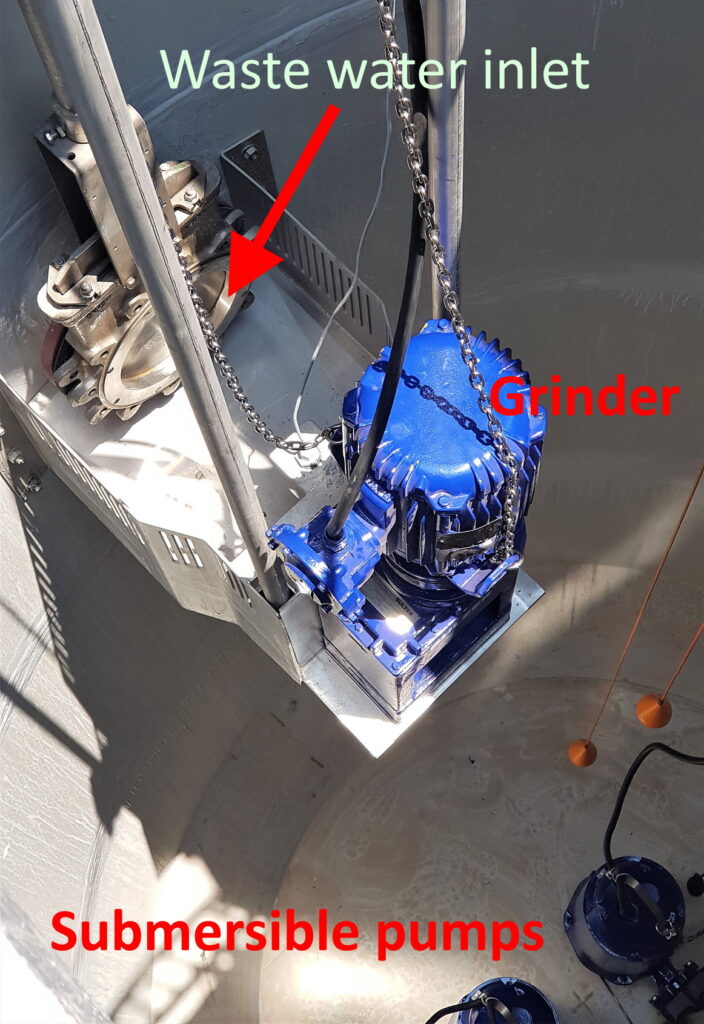

As populations grow and habits change, wastewater systems are exposed to a rising tide of difficult materials, especially tough fibrous products such as wet wipes and disposable nappies. Left unchecked, these materials can jam up pumps, reducing flow rates, driving up energy consumption and ultimately bringing operations to a halt. That leads to costly and time-consuming maintenance visits to rectify the situation. Rajeev Seth, Sales Manager Pacific – Channel Partners at Sulzer Australia, explains: “One of the most effective ways to stop wastewater blockages is with dual shaft grinder technology. Sulzer’s Muffin Monster range offers dual shaft grinders, generating the high torque required to grind difficult and large solids. They can be installed both inline and in-channel upstream of critical entry points in the wastewater network, where they go to work on unconventional waste, tearing plastic and non-plastic debris and crushing solids into small particles that flow freely through the system.”

Happier holidaymakers

Situated only 10 meters from the ocean, the pumping station serving a New South Wales holiday park faces extremely high peak loads during the busiest part of the season. When the pumps become blocked by diapers or wet wipes, the resulting overflow could run straight into the sea. That could create health risks for holidaymakers and the potential for steep fines for the park operator.

After examining the situation at the park, Sulzer NSW channel partner QMax Pumping Systems, recommended a grinder to protect the pumps. As the size and location of the pumping station precluded the installation new equipment within the existing facility, the answer was a Muffin Monster Manhole – a 1.2-meter diameter fiberglass chamber containing a channel version of the Sulzer grinder. Installation on the main sewage line leading to the pumping station was quick and simple, taking less than three weeks including all civils works. Since the installation of the new system, the park has suffered no overflows or service interruptions.

Solutions for Australia and New Zealand

As facilities around the world continue to face rising demand and pressure to keep costs under control, the reliability of key infrastructure has never been more critical. Sulzer Muffin Monster grinders are being installed in holiday parks and elderly care facilities across the UK, Europe and worldwide, providing highly effective treatment for troublesome wastewater problems.