Pleuger, the specialist in submersible pumps and motors, is laying the groundwork with its research activities to be able to adapt pumps and motors to the ever-increasing requirements of the global market. One research topic presented in this context, here as an example, deals with the efficient use of energy with the aid of artificial intelligence (AI). The focus is on the efficiency of pumps.

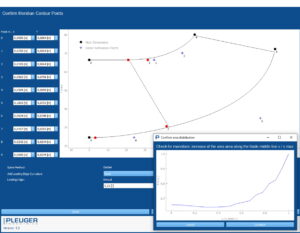

Although efficiency is a result of the design process of a pump, it must be known at the beginning in order to be able to transfer the specific work to the corresponding theoretical specific work which is required for the design process. The figure shows an example of the meridional section of a mixed flow pump whose main dimensions are a function of the efficiency.

The efficiency, which is not yet known, must be estimated when starting the calculations. A large amount of empirical data is available for this and can generally be applied with a few restrictions. The estimated value is often not the efficiency that is actually achieved after the design process of a precisely defined pump. In this case, several time-consuming iterations are required in the design to optimize the efficiency. By making use of neuronal networks, Pleuger intends to shape the design process so it will be more efficient in the future.

Processes suitable for this are being developed in cooperation with the University of Kaiserslautern, the institute of fluid mechanics and fluid machinery under the direction of Prof. Dr.-Ing. Martin Böhle. The R&D cooperative project is sponsored by the German Federal Ministry for Economic Affairs and Climate Action as part of the Central Innovation Program for small and medium-sized enterprises (ZIM).

Processes suitable for this are being developed in cooperation with the University of Kaiserslautern, the institute of fluid mechanics and fluid machinery under the direction of Prof. Dr.-Ing. Martin Böhle. The R&D cooperative project is sponsored by the German Federal Ministry for Economic Affairs and Climate Action as part of the Central Innovation Program for small and medium-sized enterprises (ZIM).

Pleuger’s key task is to develop a neuronal network that makes it easier to estimate efficiency as a function of the dimensionless specific speed of the pump. The University of Kaiserslautern in turn is developing an optimizer based on a gradient method for the contour of the meridional section, which is expected to have a positive effect on the efficiency of the pump in advance.

“Through basic research in collaboration with a university, Pleuger is able to press forward in a focused manner with decades of experience in the development of fluid machinery,” says Dr. Björn Gwiasda, Pleuger Hamburg.

The neural network will initially be set up as a simple and expandable model to be trained and tested with corresponding test data. The large volume of data from several decades of measurements on Pleuger submersible motor pumps will form the basis for training the network.

The improved estimate of the efficiency at the beginning of the design process and the optimization of the meridian should significantly reduce the development time of new pump series.

The cooperation in the area of AI described above will help make energy-efficient machines available for customers quickly in the future.