Before satellites are launched into space or a space mission commences, numerous tests have to be carried out. These tests are designed to check and ensure proper functioning in space and can only be carried out on Earth with the aid of vacuum technology. Space research has been taking place at Justus Liebig University Giessen (JLU) since the 1960s, and vacuum equipment from Pfeiffer Vacuum has been part of this from the very beginning. Today, industrial partners and space agencies test their engines under space conditions in the research group of Professor Dr. Peter J. Klar, Executive Director of the Institute of Experimental Physics I at JLU.

Ion thrusters: From a gimmick to an enabling technology

Before “New Space”, industry still regarded electric space propulsion systems as a technical gimmick that could possibly be used one day on a scientific mission. So, the field was left to university research, with a greater or lesser degree of financial commitment from industry. Today, electric space propulsion systems are regarded as “game changers”, since completely different missions can be carried out in space with these than with purely chemical propulsion systems.

At the Institute of Experimental Physics I, there are many large experimental facilities for materials research and space physics. The facilities include large vacuum chambers, in which ion thrusters can be studied in operation. These are so-called space simulation facilities. A vacuum is created in the chambers and the thrusters are tested and measured inside them. Professor Peter J. Klar explains: “Traditionally, the electric propulsion group concentrates on the development of electric space propulsion systems, especially the radio frequency ion thruster (RIT) invented by Giessen-based physicist Prof. Dr. Horst Löb.

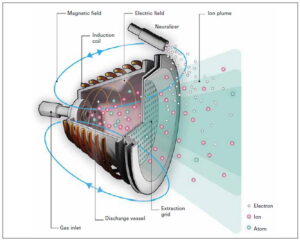

There are various types of electric space propulsion systems. The RIT thrusters developed by Prof. Löb in the 1960s have a hemispherical discharge chamber in which a plasma is ignited from the gaseous propellant. The open side of the discharge chamber is separated from space by a grid system. During thruster operation, charged propellant ions are accelerated out of the plasma and away from the thruster by the electric field applied between the grids and thus generate thrust according to the recoil principle. To prevent the spacecraft from becoming electrically charged, the positively charged ion plume must be neutralized with electrons. In the pioneering days, mercury vapor was employed as the propellant, but today the noble gas xenon is generally used. Since this is a scarce resource, however, alternatives are being actively sought”.

backing pump at the JUMBO space simulation facility for testing ion thrusters. In combination with two HiPace 2300 with Duo 65 backing pumps and eight cryo pumps, a

pumping speed of 150,000 liters of Xe per second is achieved.

Focus on the development of new test facilities

The electric propulsion group at JLU is striving to develop novel standardized test procedures. “With the commercialization of the technology, the tasks of university groups are also changing. We cannot and do not want to build large quantities of ISO 9000 certified thrusters. That is why we are concentrating on the development of novel test facilities, which is also where vacuum technology comes in,” says Prof. Klar. “We are also focusing on concepts for better thruster diagnostics and new types of miniaturized thrusters for very small satellites. We fabricate such thrusters using micro- and nanostructuring methods.”

In particular, JLU is currently setting up new test facilities, which are unique in Germany, to investigate the electromagnetic compatibility (EMC) of electric space propulsion systems. Here, tests will be carried out to determine whether the electromagnetic radiation emitted by the thruster during operation interferes with other electronics. The phenomenon is comparable to the disturbance in reception of an analog radio in a car when driving past high-voltage power lines. “These tests are immensely important if you want to operate satellites with such thrusters, because this kind of interference can lead to the complete loss of the satellite, in the worst case,” explains Prof. Klar. The EMC test facilities for testing operating thrusters must be set up quite differently to those used for standard electronics. Since the thrusters need space conditions, i.e. vacuum, in order to operate, either the EMC measurement must be carried out in the vacuum tank itself, or a vacuum tank must protrude into the shielded EMC measurement cabin.

system is also equipped with two turbopumps of the type ATH3204M with ACP 28 backing pumps.

In addition to these new facilities, the old centerpiece of Giessen’s electric propulsion research, namely the JUMBO test facility, is still in operation. It was commissioned at JLU back in the 1970s to cooperate with industry in testing RITs for use in space and was one of the first and for some period of time one of the largest in the world. In the meantime, many facilities have been built, including much larger ones. The JUMBO is now “only” the largest space simulation facility at a German university, but it has served as a model for many of the newer facilities. “We hope to have similar success in the future with the new EMC facilities. The vacuum pump infrastructure of such facilities needs to be very sophisticated. The aim is to create operating conditions that are as close as possible to those in space, because the background pressure in the vacuum chamber also determines the performance data of the thruster and, after all, we want to know how the thruster will perform in space – and not in a poor vacuum”, adds Prof. Klar.

In the field of space travel research, the scientists at JLU are also working on new types of materials that are tailored to the extreme requirements in space. Examples are GaN semiconductor structures for radiation-hard electronics. The radiation hardness can also be investigated in special test facilities at JLU and its partner institutions, whereby the semiconductors are bombarded with high-energy gamma radiation or particle radiation. Furthermore, RF ion sources similar to RITs are also used in material processing, for ion beam etching or in ion beam sputter deposition, for example.

Vacuum is essential

Vacuum technology plays an important role in this research. All the research areas have experimental facilities that have to be operated under high vacuum or even ultra-high vacuum. This applies just as much to materials research as to space research. “Various turbopump and backing pump systems from almost the entire Pfeiffer Vacuum product range are in use here”, explains Prof. Klar, “including turbopumps from the HiPace and ATH series and rotary vane pumps from the DuoLine. Magnetic bearings and corrosion protection are important features. We also benefit from the particularly long service life of the turbopumps, of course. In addition to the vacuum pumps themselves, we purchase various vacuum components, such as vacuum gauges, corrugated hoses, seals and connecting elements. The quick availability and delivery of the goods is a clear advantage here.”

“But the close interpersonal relationships with Pfeiffer Vacuum, based on trust and reliability, are especially important. There are contacts at various levels. The purely scientific exchange and discussion of scientific issues are both enjoyable and productive. This is because every new system that we design, build and operate has different requirements and also poses different challenges. For example, we have systems that require very clean vacuum, where all the pumps need to be operated without lubricants, if possible,” says Prof. Klar. “We also have systems where we work with corrosive gases such as iodine. Iodine is currently being investigated as an alternative to xenon as a propellant for ion thrusters. Here we use the HiPace 1500 C in combination with the Duo 35 MC two-stage rotary vane pump. Both pumps are designed to be resistant to corrosive gas, so that the longest possible service life within the process is guaranteed.”