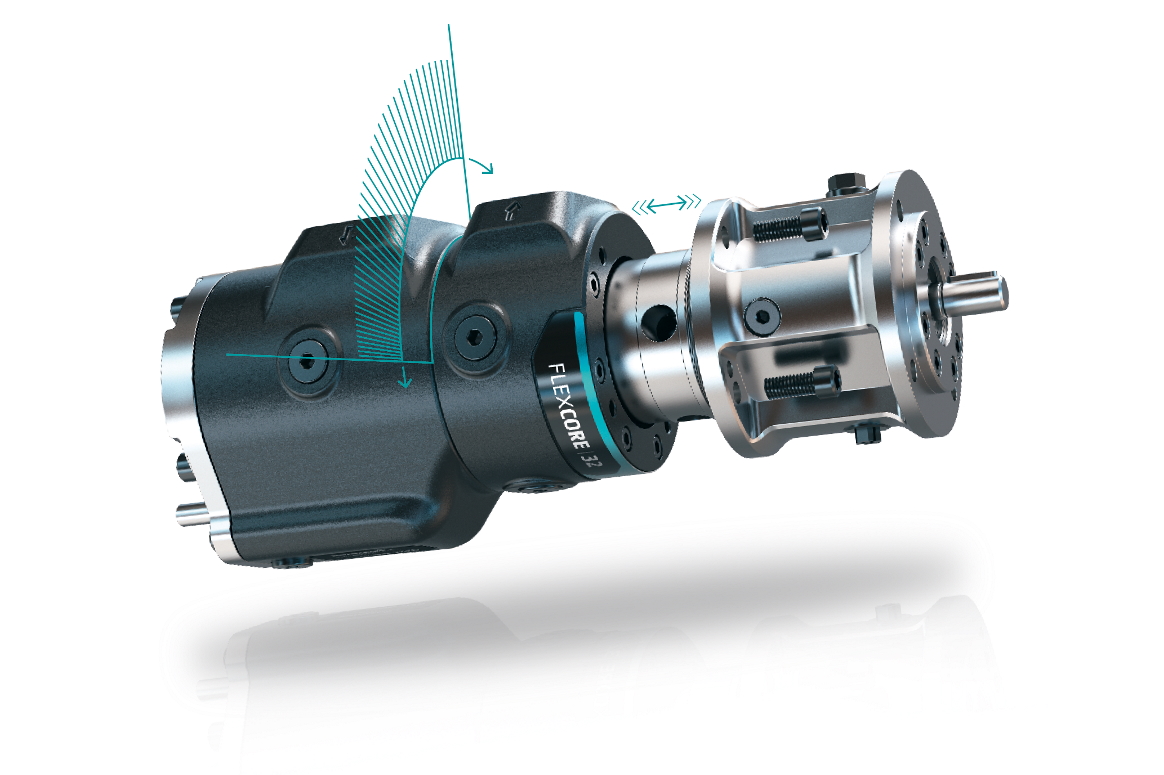

“As a specialist for demanding pump solutions, Leistritz has a clear focus: We want to optimally meet the specific expectations and needs of our customers with extraordinary products and solutions. With Flexcore, Leistritz has now created a globally groundbreaking innovation – a pump class that for the first time unites qualitative, functional and economic aspects in an extremely flexible, quickly available series product,“ explains Philipp Rossow, Product Manager at German Leistritz Pumpen GmbH. “Flexcore is the first series pump capable of adapting to a wide range of installation situations. With a single basic casing for all pressure levels, flow directions and standards. It sets new benchmarks, especially in tough applications such as power & energy, marine, chemical and petrochemical applications. Its intelligent design with the exchangeable cartridge unit is particularly impressive when it comes to installation and maintenance. Compared to conventional pumps, this modular concept is worldwide unique,” says Rossow.

Initially, Leistritz is launching pump sizes for flow rates of 7 – 564 l/min. The series will successively be expanded by eight additional sizes with flow rates up to 1,600 l/min. Depending on customer requirements, Flexcore is available in cast iron or steel casing.

Easily adjustable to different installation situations

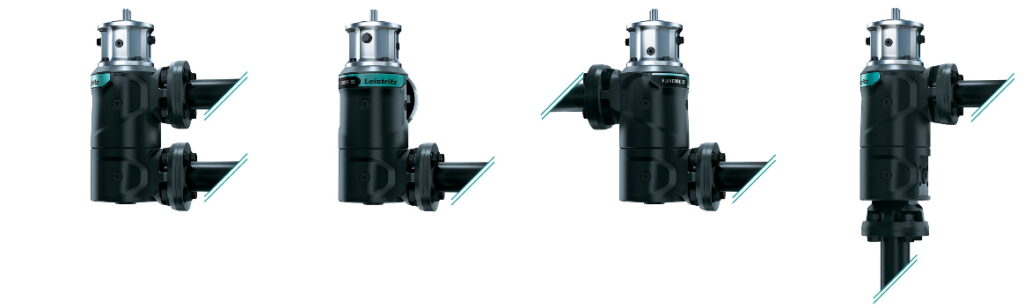

The split Flexcore casing consists of a suction and pressure part and can be rotated four times by 90°. The alignment of the optimum flange position makes the Flexcore extremely adaptable for installation – even in existing piping layouts. In addition: Depending on the application, different flange designs are possible: DIN, ASME or SAE.

High-performance pump core

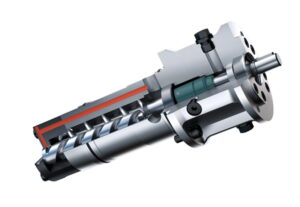

“The cartridge unit of the Flexcore is the heart of this pump,” says Rossow. Since the bearing is positioned on the outside, it is independent of the pumped medium. Therefore the Flexcore is especially suitable for low-viscous media. The seal installation space is designed for all common DIN-K mechanical seals. “We supply the pump with a very reliable standard seal, but the space allows other seals to be installed as well – depending on what the customer requires,” explains the pump expert.

Two components ensure a powerful and long performance: the fully hardened spindle package and the unique, patented thrust balancing system. “To meet the highest quality requirements, Leistritz manufactures its spindles exclusively in-house based on decades of experience”, explains Rossow. Precisely and very robustly manufactured, the profiles form an optimal basis for maximum service life. The delivery of low viscosities even at high pressures is ensured by the patented thrust compensation system: For example, pressure differences of up to 10 bar can be achieved for viscosities of 1.1 cSt. “We are the only company in the world to offer this balancing system. It can even cope with extreme operating conditions without any problems.”

Easy-to-change cartridge technology

“The main cause of premature pump failure is incorrect operation or pumping of contaminated medium,” explains Rossow. “In this worst-case scenario, every hour of failure costs the operator cash money. If you don’t have a replacement pump at hand or a service technician has to travel to the site, it will quickly end up being very expensive.” The Flexcore’s easy-to-change cartridge technology allows the pump core to be replaced in just a few minutes. This makes servicing a Flexcore easier than ever before, because not the entire pump but only the cartridge itself can be changed. “All cartridges that we deliver have of course been tested extensively on our own test benches”, says Rossow. This service aspect brings important advantages for the plant operator: enormous time and cost savings as well as simple handling, as the pump components can be replaced very easily by the plant’s own technicians.

Here a Flexcore YouTube Video:

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

https://flexcore.leistritz.com