The water supply and the related risk of a water shortage is a critical topic in many countries in the Middle East and North Africa. This is also the case in Tunisia because the existing resources are being more and more impacted by shortages. Currently, agriculture in Tunisia accounts for almost 80 % of total water consumption, around 15 % is for drinking water, and the rest is for industry and tourism.

However, the use of conventional water sources to cover the demand is already very intensive and is being depleted increasingly due to population growth, improved living standards, and climate factors. Taking account of the climatic and also other factors, current forecasts say that the resources available will be completely exhausted by around 2030 and will then gradually run dry. Effective management of these water resources by means of constant monitoring and control as well as reforms in the water sector are thus vital.

Comprehensive strategy for irrigation and drinking water supply

With this in mind, Tunisia has developed complex and diverse water infrastructures that enable the country to make better use of the sources available. At the same time, the government has introduced various regulations and laws in order to guarantee that the majority of the urban and rural population has better access to drinking water and to safeguard a sustainable supply for agricultural irrigation, industry, and tourism.

In addition, the World Bank announced a 140-million US dollar project in May 2018 to support the Tunisian government in improving agricultural irrigation by managing scarcer water resources and new business opportunities, especially for underdeveloped rural areas. Irrigation alone requires around 80 percent of the country’s entire water potential. Among other things, the project will finance modernization of and repairs to the irrigation system in order to make it more effective and reliable.

Similarly, the demand for drinking water in rural areas will rise to 60 million cubic meters per annum by 2030 according to current forecasts. As a result, the Tunisian President Youssef Chahed announced a new national strategy in June 2018 to conserve water resources. The goal is to safeguard water supplies by building dams and inland lakes, and by drilling boreholes as well as implementing some deep-sea projects.

New pumping plant on Cap Bon

The Société Nationale d’Exploitation et de Distribution des Eaux (SONEDE) is responsible for the water supply in both urban and rural areas of Tunisia. This national water supply authority is a public institution, but also an autonomous one, attached to the Ministry of Agriculture. It was established in 1968 and is responsible for production, including water treatment and transport, management and maintenance of the drinking water network as well as development of the water sector.

As part of the national strategy to safeguard a sustainable water supply, SONEDE is building a new pumping station on the Cap Bon peninsula. The Medjerda River will supply water to this plant. With a length of 450 kilometers, this is not only the longest river in Tunisia, it also feeds more than half of the water supply network throughout the country. The plant treats 150 cubic meters of river water per day for drinking water and distributes it in the Nabeul, Hammamet, Korba, Kelibia and Menzel Temime regions.

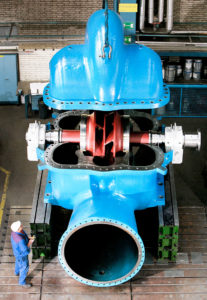

Pumps play an essential role in this supply process. As a result of having the best price-performance offer, highest efficiencies and good relations with EPC Socoopec, Andritz was awarded the order to supply the pumps for the station. The international technology Group will manufacture and supply a total of nine double-flow axial split-case pumps from the ASP series.

The pumps expert for drinking water supplies

Pumping systems from Andritz make an essential contribution worldwide towards a safe, sustainable and, above all, technologically optimized water supply. The mega-city of Peking also trusts in this technology and quality. Hui Nan Zhuang pumping station located to the south-west of the Chinese capital is equipped with eight double-flow axial split-case Andritz pumps. Two sets of three pumps plus one standby unit each supply a common pipe with a diameter of four meters. Hui Nan Zhuang is the only pumping station in the middle water supply channel of the Chinese milestone project “South-to-North Water Diversion”, with a total length in the region of 1,200 kilometers. The pumps supplied by Andritz convey a total of 60 cubic meters of water per second over a distance of approximately 60 kilometers to Peking.

Nine smaller pumps of this same type will also be used in the new drinking water plant on Cap Bon. They are the ideal hydraulic machines for use as piped water pumps in water treatment or drinking water pumps in water supply systems. Depending on the final location of the Tunisian pumping station, it will handle a flow rate of 648 to 900 m³/h at heads of 20 to 63 meters. For this purpose, each pump is fitted with a 55, 160 or 200 kilowatt motor. With an efficiency of up to 91 percent, these double-flow split-case pumps help to save valuable energy. All of the pumps are equipped with a twin-flow radial impeller that achieves very favorable NPSH levels. Thanks to the axial split-case design, maintenance work is quick and easy. Equipped with a double-flow radial impeller and an inline casing, the pump can be installed horizontally or vertically. If mounted horizontally, the motor(s) can be positioned on the left and/or on the right.

Besides design and delivery of the pumps and spare parts, installation and commissioning work on site will also be supervised by Andritz personnel. Completion of the entire project is scheduled for June 2019.

Equipped for the future

In addition, the pump casing already has the connections needed for intelligent sensors to monitor operating reliability and performance as well as other key indicators in line with Industry 4.0. These special pump monitoring packages that can also be retrofitted compare operating conditions against the nominal curves. These include variable speed curves such as head, efficiency, motor rating or NPSH in relation to flow rates. In addition, temperature, vibration and electrical analyses are conducted. All data can be analysed in the software or exported to various file formats. The files are stored in an Andritz Metris data base that can be installed on a local server or remotely in the Andritz Metris Cloud (Microsoft Azure).

Based on these data gathered, accessible by the customer and by Andritz condition monitoring experts, service recommendations can be provided at any time for operation of the plant and the pumps installed. By standardizing data acquisition with these tools, the customer’s experts can also communicate more effectively with Andritz and improve plant performance at the same time. By networking our customers’ own specialists, also with Andritz experts, our IIoT technologies become the basis for Internet-of-People (IoP) solutions. This value-adding connection results not only in professional processing of the data gathered, which improve and maintain the performance of the plant, but make it possible in addition to respond and react even better to climatic and other factors that have an adverse effect on the water supply.

Andritz Group

Andritz is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where Andritz offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

Andritz stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, 29,000 employees, and more than 280 locations in over 40 countries worldwide, Andritz is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.